Toothpaste Manufacturing: Ingredients, Process & Trends

Toothpaste is a cornerstone of daily oral care, combining science and practicality to keep smiles healthy. As a trusted manufacturer, Lidercare crafts high-quality toothpaste products that meet modern consumer needs. Let’s break down the essentials of toothpaste manufacturing, current trends, and how we deliver custom solutions for brands.

Key Toothpaste Ingredients

Every toothpaste formula relies on core ingredients to clean, protect, and freshen teeth. Here’s what goes into a typical tube:

Abrasives

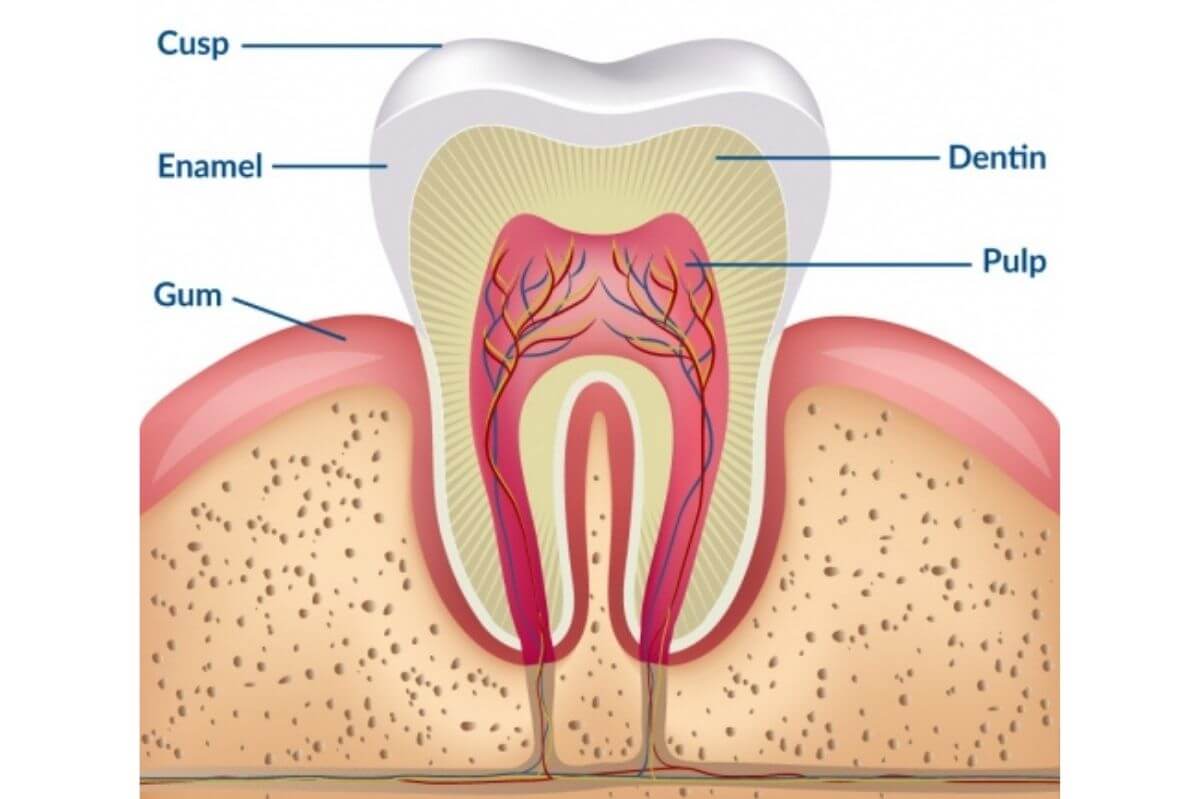

Calcium carbonate or silica gently scrub away plaque and stains without harming enamel.Fluoride

This cavity-fighting mineral strengthens enamel and prevents decay.Humectants

Glycerin or sorbitol keep toothpaste moist and smooth.Detergents

Sodium lauryl sulfate creates foam to spread the paste and rinse debris.Flavors

Peppermint, spearmint, or other natural oils provide a fresh taste.Active Agents

Specialized ingredients target specific needs:Hydroxyapatite: Repairs enamel and reduces sensitivity.

Charcoal: Absorbs stains for whitening.

Enzymes: Break down plaque and bacteria.

How Toothpaste Is Made

The manufacturing process ensures consistency, safety, and effectiveness. Here’s how Lidercare does it:

Mixing

Dry ingredients (abrasives, fluoride) blend with liquids (humectants, water, flavors) in industrial mixers.Homogenizing

The mixture passes through machines to eliminate clumps and create a uniform texture.Deaeration

Air bubbles are removed to prevent gaps in the final product.Filling & Packaging

Automated systems fill tubes, seal them, and apply labels.Quality Checks

Every batch undergoes tests for fluoride levels, texture, and microbial safety.

Trends Shaping Toothpaste Manufacturing

The oral care industry adapts to consumer preferences and innovation. Key trends include:

Natural Formulas

Demand grows for plant-based ingredients, free from artificial additives.Eco-Friendly Packaging

Brands switch to recyclable tubes and biodegradable materials.Specialized Solutions

Products target specific issues like sensitivity, whitening, or gum health.New Formats

Tablets, foam, and pens offer convenience for travel and minimal waste.Oral Microbiome Support

Formulas now include probiotics to balance mouth bacteria.

Try Lidercare Now!

We Help You Launch New Products, And Continue To Grow. Try Us With 20% Off Your First Order!

Lidercare: Innovating Custom Toothpaste Solutions

As a leader in oral care manufacturing, Lidercare offers tailored services to meet brand goals. Our expertise covers:

Whitening Toothpaste: With charcoal or peroxide-based formulas.

Enamel Repair: Hydroxyapatite-infused options.

Eco-Conscious Products: Biodegradable packaging and natural ingredients.

Private Labeling: Custom flavors, textures, and packaging designs.

Why Partner With Lidercare?

Flexible Formulas

Adjust ingredients to target whitening, sensitivity, or fresh breath.Fast Turnarounds

Efficient production meets tight deadlines without compromising quality.Sustainability Focus

Choose recyclable tubes or refillable containers to align with eco-values.End-to-End Support

From concept to packaging, we guide brands through every step.

Conclusion

Toothpaste manufacturing blends precision, innovation, and consumer insight. By understanding ingredients, processes, and trends, brands can create products that resonate with today’s shoppers. Lidercare empowers businesses to stand out with custom solutions—whether it’s a natural whitening paste or a microbiome-friendly formula.

Ready to develop your unique toothpaste line? Contact Lidercare to start your journey toward oral care innovation.

Table of Contents

Awesome! Share to:

Latest Blog Posts

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.