Manufacturer's Guide: How to Make Toothpaste Tablets

Introduction

Toothpaste tablets are a game-changing innovation in oral care, offering convenience, eco-friendliness, and precise dosing. As more consumers seek sustainable and travel-friendly alternatives to traditional toothpaste tubes, oral care brands have a prime opportunity to diversify their product lines by manufacturing toothpaste tablets. In this guide, our company Lidercare walks you through everything you need to know—from the base ingredients and specialized equipment to a step-by-step production process—so you can bring high-quality toothpaste tablets to market.

What Are Toothpaste Tablets?

Toothpaste tablets are small, solid pellets designed to dissolve into a cleansing paste when chewed or mixed with water. They deliver all the cleaning power of a standard toothpaste in a compact, plastic-free form. Key advantages include:

Portability: Ideal for travel, camping, or daily commutes without worrying about leaks or TSA restrictions.

Eco-Friendly: Typically packaged in recyclable or biodegradable containers, significantly reducing plastic waste.

Consistent Dosing: Each tablet contains a precise amount of active ingredients, eliminating guesswork and overuse.

Core Ingredients

Depending on your target formulation—fluoride or fluoride-free, whitening, herbal, or sensitive—you’ll assemble a blend of the following components:

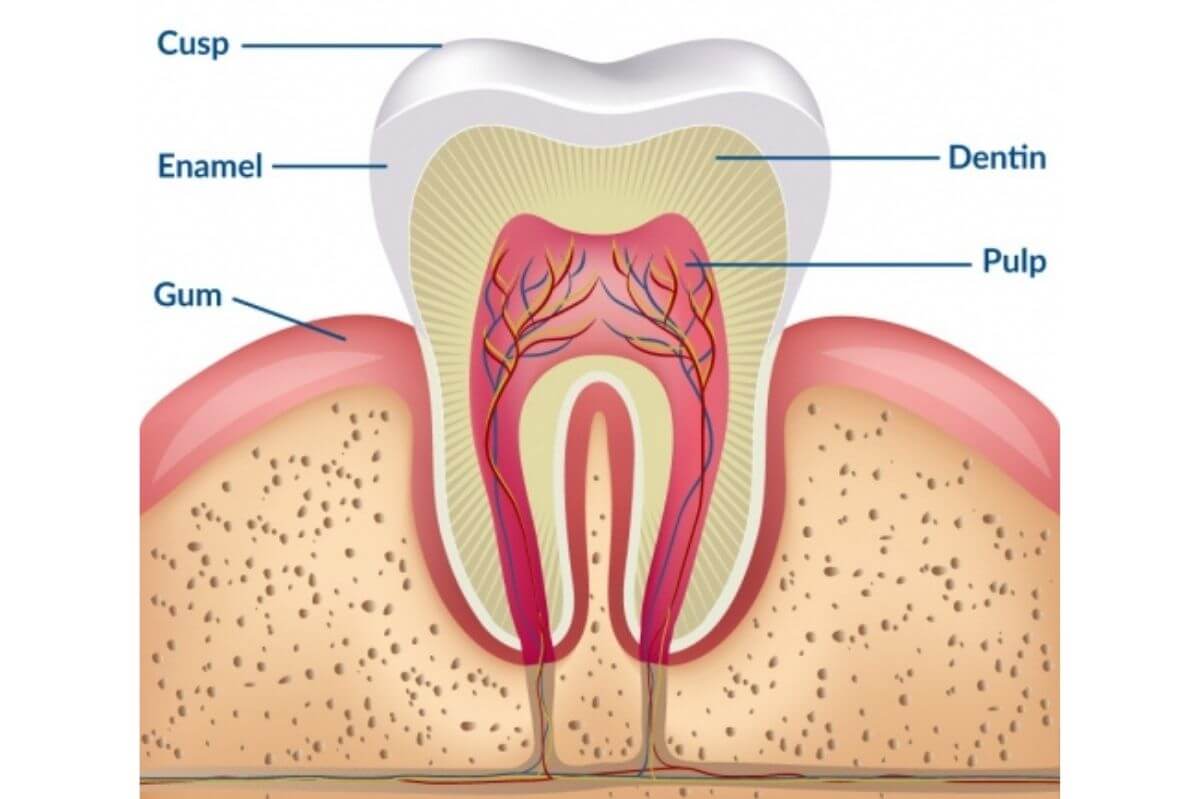

Abrasives: Mild cleansers like calcium carbonate or hydrated silica to scrub away plaque and surface stains.

Binders: Agents such as xanthan gum or cellulose gum that hold the tablet’s structure and create a smooth paste upon dissolution.

Humectants: Ingredients like sorbitol or glycerin to retain moisture in the tablet and mouth.

Flavoring Agents: Natural or artificial flavors—mint, cinnamon, or fruit extracts—for a fresh, palatable brushing experience.

Sweeteners: Xylitol, stevia, or sorbitol to enhance taste and support dental health by reducing cavity-causing bacteria.

Active Ingredients: Sodium fluoride or alternative minerals for enamel strengthening and cavity prevention; herbal extracts or essential oils (e.g., peppermint oil) for added therapeutic benefits.

Optional Additives: Enzymes for plaque control, whitening agents like hydrogen peroxide, or desensitizing compounds for sensitive teeth.

Essential Equipment

To ensure scalable, consistent production, set up the following machinery:

Mixing Tanks: Stainless-steel vessels with agitators for homogenous blending of dry powders and liquids.

Extrusion Machines: Devices that shape the mixed paste into continuous rods or ropes, which are then cut into tablet-sized segments.

Tablet Presses: High-pressure presses equipped with custom punches and dies to compress segments into uniform tablets.

Drying Ovens: Controlled-temperature chambers to eliminate excess moisture and stabilize tablet integrity.

Coating Units: Optional spray or pan coaters to apply protective layers that improve shelf life and reduce dust.

Packaging Lines: Fillers and sealers for jars, tubes, or sachets—optimized for recyclable or compostable materials.

Step-by-Step Manufacturing Process

Formulation Development: Accurately weigh and combine powders, liquids, and active ingredients according to your recipe. Conduct small-batch trials to fine-tune texture and flavor.

Mixing: Transfer raw materials into the mixing tank. Blend at controlled temperatures and speeds until a uniform paste is formed.

Extrusion: Feed the blend through the extrusion machine to form a continuous rope. Monitor diameter and consistency to ensure downstream tablet uniformity.

Cutting: Slice the extruded rope into evenly sized segments using a precision cutter.

Compression: Load segments into the tablet press. Adjust pressure and dwell time to achieve the desired hardness and dissolution profile.

Drying: Spread compressed tablets on trays and dry in ovens at 45–60°C until moisture content drops below 2%.

Coating (Optional): Apply a thin protective coating for aesthetics, flavor preservation, and moisture resistance.

Packaging: Automated lines fill and seal tablets into final containers. Include proper labeling with batch codes and expiration dates.

Quality Control and Testing

Appearance & Uniformity: Inspect tablet shape, size, and color consistency.

Hardness & Friability: Measure mechanical strength and resistance to chipping.

Disintegration & Dissolution: Verify that tablets break down within 30–60 seconds.

Microbial Testing: Ensure zero contamination following ISO 22716 standards.

Fluoride Content (if applicable): Confirm active ingredient levels via titration or spectrophotometry.

Tips for Success

Source High-Purity Raw Materials: Partner with certified suppliers to ensure ingredient consistency.

Start with Pilot Batches: Use small-scale equipment to optimize your formulation before full-scale production.

Document Every Step: Maintain detailed batch records for traceability and regulatory compliance.

Conduct Shelf-Life Studies: Test tablets under various conditions to establish an accurate expiration date.

Iterate on Flavor Profiles: Consumer feedback on taste and texture is crucial for repeat purchases.

Marketing Strategies

Highlight Sustainability: Emphasize plastic reduction and eco-friendly packaging in your branding.

Promote Convenience: Position tablets as the perfect travel and gym companion.

Leverage Social Proof: Share influencer endorsements and user testimonials across digital channels.

Bundle Offers: Create trial packs or subscription services to encourage customer loyalty.

Try Lidercare Now!

We Help You Launch New Products, And Continue To Grow. Try Us With 20% Off Your First Order!

Conclusion

By integrating precise formulation, robust equipment, and stringent quality checks, our company Lidercare empowers brands to successfully manufacture toothpaste tablets that meet consumer demand for eco-conscious, convenient oral care. With the right processes and marketing tactics in place, you can introduce a standout product and capture a growing segment of the oral hygiene market.

Frequently Asked Questions

What makes toothpaste tablets different from traditional toothpaste?

Unlike traditional pastes, tablets are solid, pre-measured doses that dissolve into a paste when chewed, offering mess-free, portable, and eco-friendly oral care.Can toothpaste tablets contain fluoride?

Yes. Many formulations include sodium fluoride for enamel strengthening, while some cater to fluoride-free preferences using alternative minerals.How long do tablets take to dissolve?

Most tablets fully disintegrate in 30–60 seconds, depending on the binder type and compression force.Are toothpaste tablets safe for children?

Formulations can be tailored for children by adjusting abrasive levels, flavors, and safe sweeteners like xylitol; always include age-appropriate dosing instructions.What packaging options are best for toothpaste tablets?

Recyclable jars, biodegradable pouches, and compostable paper tubes rank highest for sustainability and consumer appeal.How should I store toothpaste tablets?

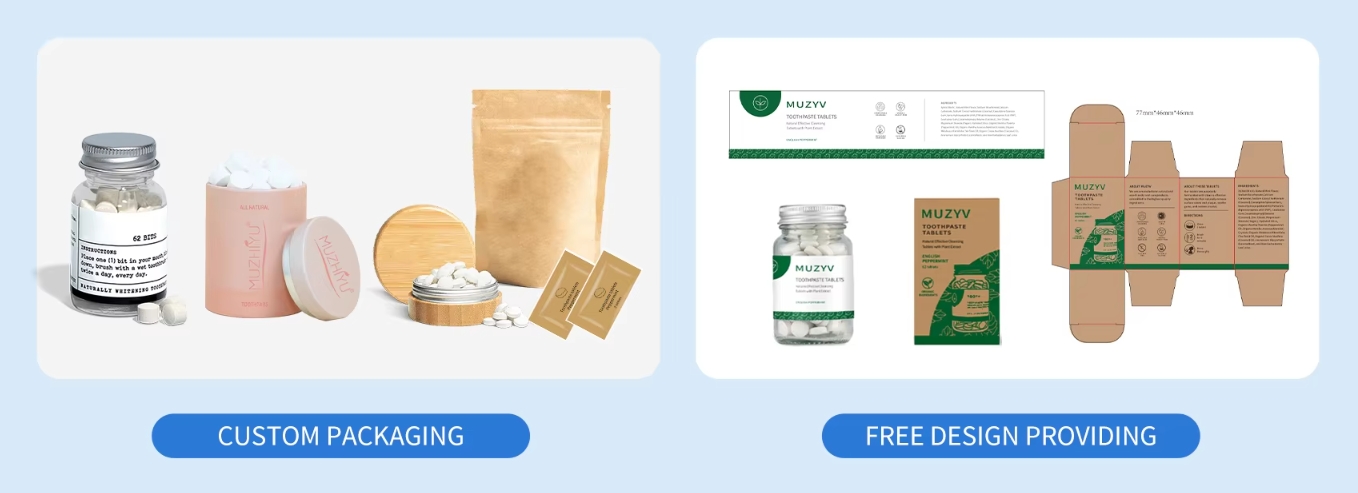

Keep tablets in a cool, dry place away from humidity to prevent premature dissolution or clumping.Can I customize flavors and colors?

Absolutely. Flavor oils, natural colorants, and herbal extracts allow full customization to match your brand identity.What are common quality control tests for toothpaste tablets?

Key tests include hardness, friability, disintegration time, microbial limits, and active ingredient assay.Is specialized equipment necessary for production?

Yes. Extruders, tablet presses, dryers, and packaging machines ensure consistent quality and scalable output.How do I determine the right tablet size and shape?

Conduct pilot trials to test consumer preference for mouthfeel, dissolving time, and ease of use—then optimize punch designs accordingly.

Table of Contents

Awesome! Share to:

Latest Blog Posts

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.